Suitable product size: φ15-120*H250mm;

Output: 3000-7000pcs/H;

Adjustable height of lifting frame: 800-1300mm;

Power: 2KW;

Mechanical size: length 2200* width 1050* height 1900mm;

Weight: 380KG;

Suitable product size: φ15-120*H250mm;

Output: 3000-7000pcs/H;

Adjustable height of lifting frame: 800-1300mm;

Power: 2KW;

Mechanical size: length 2200* width 1050* height 1900mm;

Weight: 380KG;

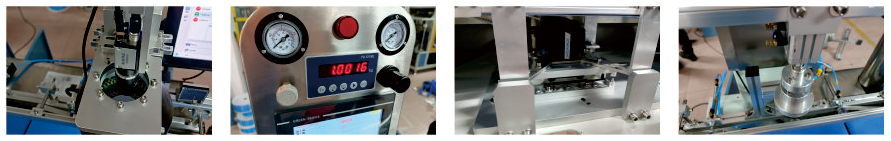

1. Technical background: Under the phenomenon of difficult recruitment of blow molding enterprises, unstable product quality, customer complaints and returns, the Panguan team has integrated the functions of vision (single camera), weighing machine and leak detection machine through in-depth research and technical public relations.

2. Device function description: The bottles enter the vision machine (single camera) through the previous process, and solve the problems [1 bottle mouth raw edge, 2 bottle mouth missing material, 3 bottle mouth deformation, 4 bottle mouth blocked glue, 5 bottle shoulder more than 0.2mm black spots, 6 bottle closing line is obviously thick, 7 bottle mouth size abnormal], through the weighing machine, solve the problems [bottle weight is too light or too heavy], and then through the leak detection machine, Solve the problem 【 Identify whether the bottle is leaking inside 】

3. The advantages of the European vision software system are as follows: 1> easy to set tasks, 2> fast time to replace products, 3> stable system repeatability, 4> high precision;

4. Weighing station source with Germany Siemens PLC high-precision weighing module and mature control system.

5. Leakage station source with Europe's improved leakage detection technology: 1> Germany Siemens PLC control stability, 2> easy to change bottle type, 3> easy to adjust, 4> high leakage detection accuracy.